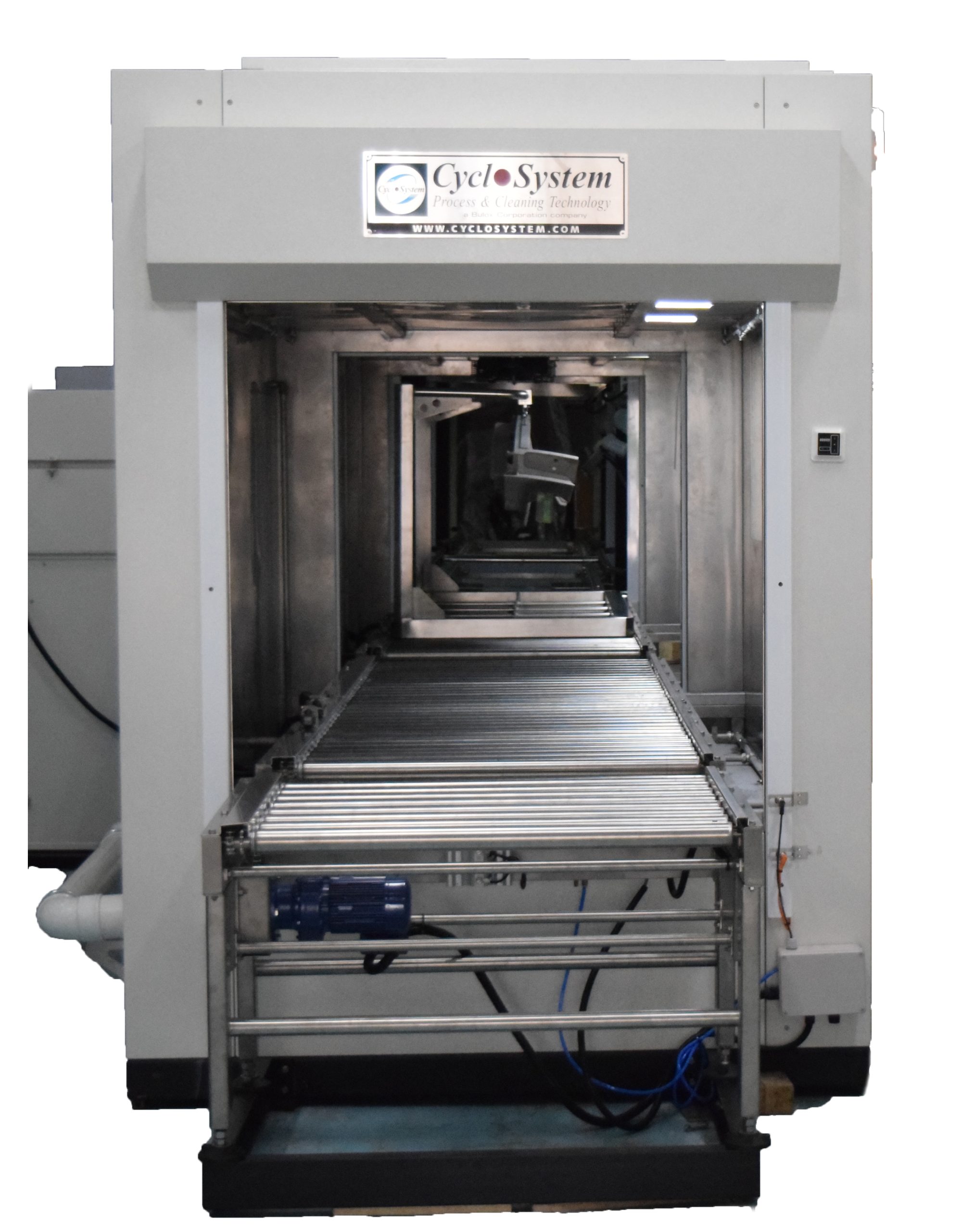

Description

The Fluorescent Penetrant Inspection (FPI) System is a Non-Destructive Testing (NDT) solution used to detect surface cracks on moving or rotating mechanical parts. This method is commonly applied in the inspection of engine components and other critical parts, particularly in the Aerospace Maintenance, Repair, and Overhaul (MRO) industry.

The complete NDT process includes cleaning, drying, penetrant application, and developer processing within a controlled environment, followed by inspection under UV light in a darkroom to reveal surface defects.

With extensive experience in cleaning and process automation, Cyclosystem has pioneered the development of automated FPI and Etching Lines, significantly reducing process time without compromising test accuracy or NDT standards. The company is recognized as one of the first in the region to successfully design and supply a fully automated FPI line.

To address diverse customer needs, Cyclosystem has standardized its Auto-FPI Systems into the following formats:

- Compact FPI System – for small parts

- Manual FPI System – customized for large parts

- One-Piece-Flow Type

- Small-Batch-Flow

- Large-Batch-Flow

- Robotic FPI System – for irregular or complex components

Cyclosystem also designs and supplies robotic FPI systems for handling parts with complex geometries, ensuring consistency, precision, and efficiency in defect detection.